Deformation of a staple due to bending

Staplers are common sights in offices. Fig. 4-8 shows a typical stapler which creates closed staples through a process of bending and plastic deformation. In this case it can be seen that the two symmetric indents or grooves in the front part of the base of the stapler have bowed shapes.

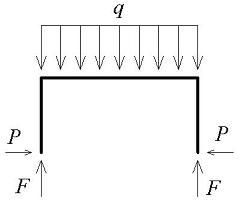

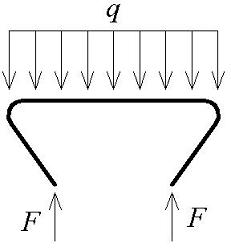

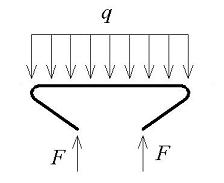

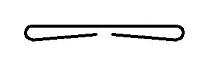

Fig. 4-9 shows the process of the deformation of a staple by the stapler. Initially a staple looks like a frame structure without supports at the two ends of the two vertical elements. When the stapler is depressed, distributed loads are applied on the horizontal element (the middle part of the frame) and these loads push the staple through the multiple sheets of paper being joined to meet the metal base of the stapler. When the staple reaches and enters the grooves in the base, both vertical and lateral forces are applied to the ends of the staple as shown in Fig. 4-9a. The lateral forces, which are induced due to the shape of the grooves, make the two vertical elements of the staple bend and move inwards. When the staple reaches the position shown in Fig. 4-9b, the ends of the staple leave the grooves and no lateral forces act. In this position the vertical forces are sufficient to continue to bend the two vertical elements further (Fig. 4-9c). Finally, the staple reaches the shape shown in Fig. 4-9d. The large deformations induced are plastic and permanent.