Model 4: The core of a section

The models demonstrate that the stress will be of the same type, compression or tension, throughout a section if a vertical load is applied within the core of the section.

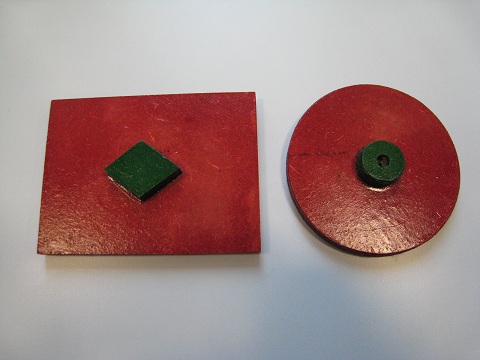

Figure 6.A3: Rectangular and circular sections with their core areas

Figure 6.A3 shows rectangular and circular pieces of wood on which the core areas are marked in green on the tops of the pieces. The demonstrations show the effects when a vertical compressive load is applied within and outside of the core areas when the two wooden pieces are placed on a sponge blocks.

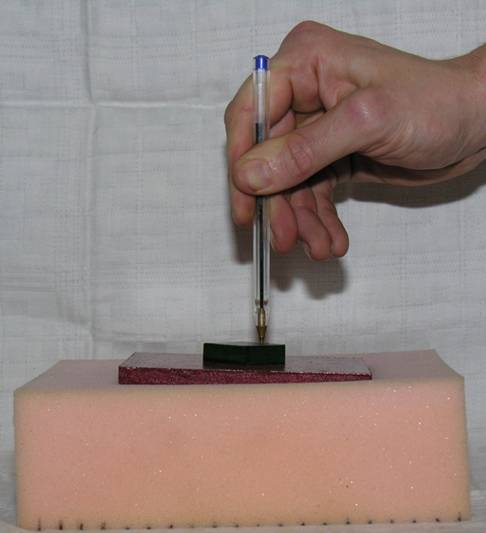

Figure 6.A4: A rectangular section subject to a vertical load

When an eccentric compressive load is applied perpendicular to the core area of the rectangular section as shown in Figure 6.A4a, it will cause both a uniform stress distribution and a linearly distributed stress distribution in the sponge block under the section. The uniform stress distribution is due to the action of the compressive load if it is applied at the centre of the rectangle while the linearly distributed stress is induced by the bending moment that is the product of the load and the distance between the point of the load and the centre of the rectangle. In this case, the maximum stress induced by the moment is smaller than the uniform stress. Thus all the areas of the wooden piece are subjected to compressive stress. In other words, the whole area of the rectangle is in contact with the sponge and there are no gaps between the wooden piece and the sponge.

When the load is applied outside of the core area, the linearly distributed stress will increase proportionally with the distance between the load point and the centre of the rectangle. In this case (Figure 6.A4b), the maximum stress due to the moment is larger than the uniformly distributed stress and this causes a separation between the wooden piece and the sponge resulting in a stress redistribution.

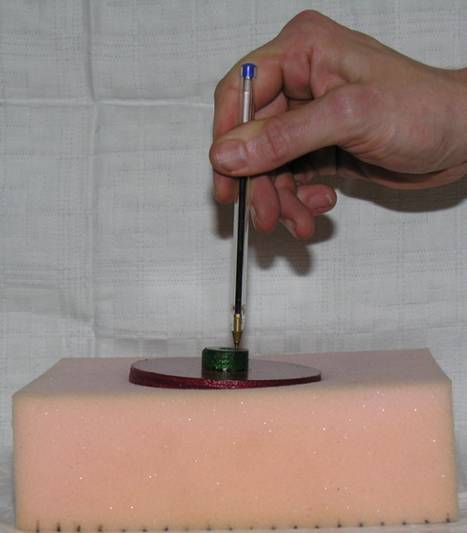

Figure 6.A5: A circular section subject to a vertical load

The same experiment can be repeated with the circular wooden section and similar results can be observed from Figure 6.A5. The experiments demonstrate that:

- When the load is applied within the core area, the stress applied on the wooden piece is all compressive, maintaining whole contact with the sponge (Figure 6.A5a).

- When the load is applied outside of the core area, separation occurs between part of the wooden section and the sponge with the contact area experiencing larger non-uniform stresses than the case when the load is applied within the core (Figure 6.A5b).