Effect of shear stress

This demonstration shows the existence of shear stress in bending and how shear resistance/stresses between beams/plates/sheets can significantly increase the bending stiffness of a beam.

Fig. 5-6: Effect of shear stress in catalogues

Take two identical thick catalogues and drill holes through one of them and then put bolts through the holes and tighten the bolts as shown in Fig. 5-6a. Place the two catalogues on a wooden board up against two wood strips, say a quarter the thickness of a catalogue, which are secured to the board and apply a horizontal force at the top right edge of each of the two catalogues as shown in Fig. 5-6b. It is apparent that the thin pages slide over each other in the unbolted catalogue while in the bolted catalogue there is no movement of the pages. This is because the bolts and the friction between the pages provide horizontal shear resistance and prevent the pages sliding between each other.

Support the two catalogues at their ends on two wooden blocks on the board as shown in Figs. 5-6c and 5-6d and place the same weight at the mid-span of each of the two catalogues. Fig. 5-6c and 5-6d show the bending deflections of the two catalogues with the unbolted catalogue experiencing large deformations while the bolted catalogue experiences only small deformations. The bolts and the friction between the pages provide horizontal shear resistance between the pages of the bolted catalogue and make this act as a single member, a 'thick' beam or plate, whereas in the unbolted catalogue the pages act as a series of very 'thin' beams or plates.

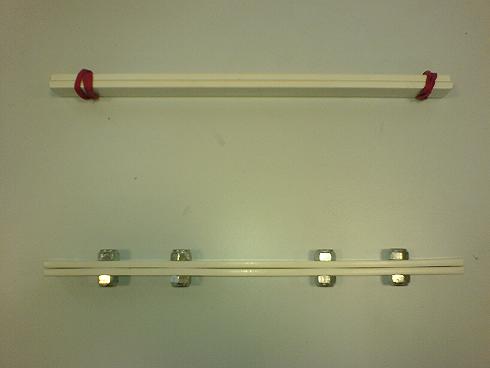

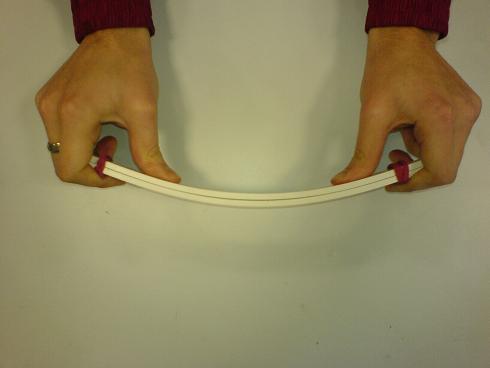

Fig. 5-7: Effect of shear resistance in beams

A similar but simpler demonstration of the effect of shear stress can be demonstrated using beams made up of two strips of plastic as shown in Fig. 5-7a. For one beam the two plastic strips are loosely bound with elastic bands and for the other beam the two plastic strips are securely held together with four bolts that act as shear connectors and, because of the tension in the tightened bolts, provide compressive forces on the two strips. Suitable sizes for the strips would be 300mm long, 25mm wide and 10mm thick.

By applying similar forces to the ends of the beams one can observe and feel the effect of the shear connection. When bending the beam without shear connectors, one can see the two strips rub against each other and slightly move relative to one another. This becomes noticeable at the ends of the strips as there is little shear resistance between the two strips. When bending the beam with shear connectors, one can feel that the beam is much stiffer than the beam without shear connectors and it is possible to see that there is no relative movement between the strips.